Pipes have been an essential component of plumbing, heating, and industrial systems for a considerable measure of time. They are adaptable, last for a long time, and may be used in a variety of different ways. Nevertheless, how can we make them conform to the precise form that we require? The trade of pipe bending, which has been practiced for more than a century, is the solution to this question. Not only does the art of pipe bending include the shape of metal tubes, but it also involves the creation of a masterpiece that is capable of withstanding even the channel of time. When it comes to the art of pipe bending machine we are going to inform all of the secrets in this blog.

About Pipe Bending Machine

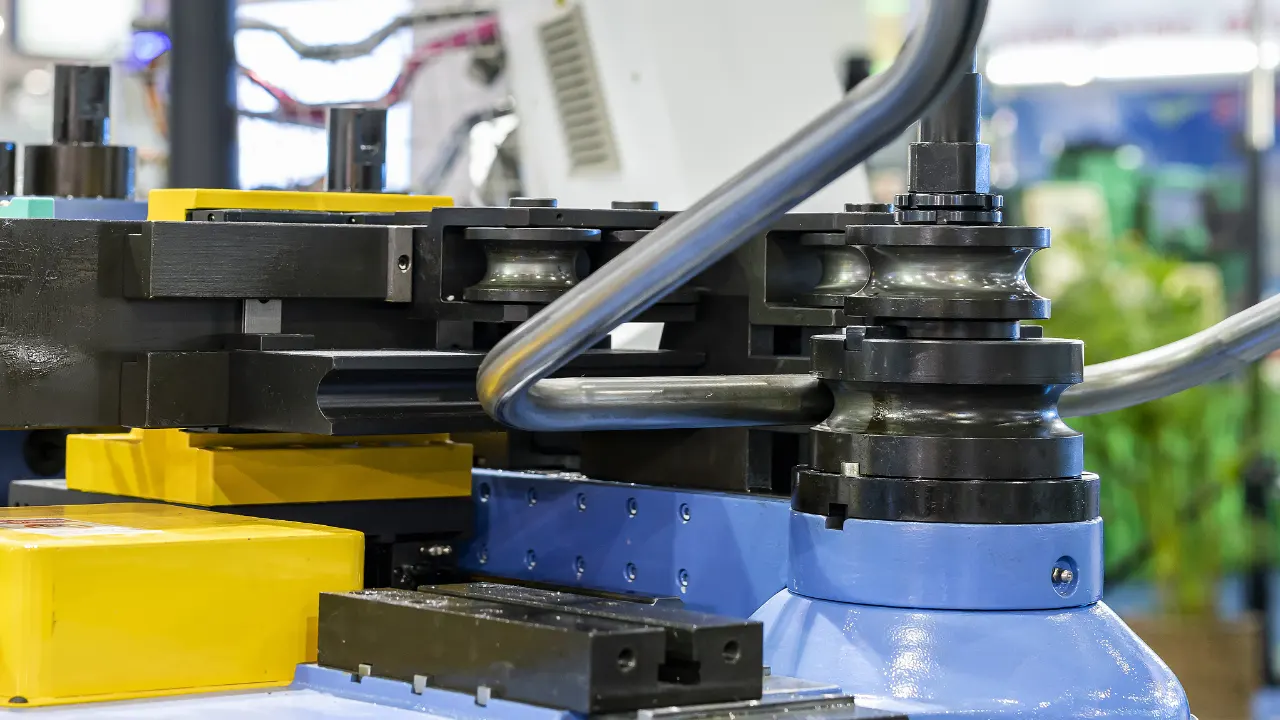

The pipe bending machine is made of steel and is simple to use. It is a highly practical piece of equipment for work that is mobile. Additionally, it is convenient to take about and use whenever and wherever you choose. The amount of human labor that is necessary to figure out this machine is reduced, and it also requires a lower level of expertise. On the other hand, we are inclined to meet live arising with a roller bending machine that is handled by hand and uses a block, motors, gears, and support (frame).

It is the power that drives the machine that bends pipes, while everyone else does their task manually. Because of this, the goal of pipe bending machine manufacturers is to increase the precision of their machines while maintaining their cheap prices and maintaining the same level of output.

The History And Evolution Of Pipe Bending Techniques

The practice of pipe bending has a long and illustrious history that goes back hundreds of years. Evidence of primitive pipe bending methods may be traced back to ancient civilizations such as the Egyptians, Greeks, and Romans. The precise origins of these skills are unknown, although they can be established as far back as ancient times. Early versions of pipe bending were exploited by these civilizations in order to construct sophisticated plumbing systems, aqueducts, and even beautiful constructions.

Beginning in the early days of pipe bending, the majority of the work was done by hand, using only basic equipment and methods. A condition of malleability would be achieved by skilled artisans by heating the metal pipes in furnaces or over open flames until they reached the desired temperature. In order to get more exact bends, they would often make use of crude jigs and molds. After that, they would painstakingly shape the pipe themselves using their hands.

Over the course of time, developments in manufacturing processes and technological breakthroughs brought to a revolution in the process of pipe bending.

This pipe bending machine has a number of primary applications, which are listed below.

- This particular machine contributes to the ease with which metal sheets may be bent.

- Without the need of any energy, it is able to bend the sheet.

- By means of manual operation, the work was completed at the domestic level.

- Additionally, it is advantageous in terms of migrating from one location to another.

- This equipment eliminates the need for work that is physically demanding.

- It is simple to manipulate and operate.

- There is a little amount of maintenance being needed for devices of this type.

Why It Is Important To Invest In The Appropriate Machine

For anybody who is interested in becoming an expert in the art of pipe bending and transforming their work, it is essential to make an investment in the appropriate equipment. In spite of the fact that it could be tempting to go with a model that is either older or less expensive, sacrificing quality might result in a multitude of difficulties and constraints in the long term. The many kinds of activities that may be performed on metal sheets are performed by bending machines, which are used extensively in industries all over the globe. When compared to the other machines, the size of these machines is much larger than the other machines. The metal sheets are bent with the assistance of these machines, which include a large number of components.

Bottom Line

As was previously said, having the appropriate machine may drastically improve the quality of your job and take your abilities to bend pipes to the next level completely. Pipe bending machine manufacturers utilize advanced technologies and materials to ensure durability, accuracy, and versatility in their products.